Five trends in sustainable manufacturing for 2024

In a rapidly evolving world, sustainable manufacturing has become the cornerstone of effective strategy and planning. As companies and industries continue to grapple with the complexities of our time, keeping abreast of key sustainability trends has become an imperative.

In this blog we discuss 5 trends that are likely to feature heavily in the debate around sustainable manufacturing for 2024.

1. New rules about corporate sustainability reporting

Back in November 2022 the European Parliament adopted the Corporate Sustainability Reporting Directive. This is a set of rules requiring companies to publish regular reports on how their activities impact people and the environment. In January 2023 the directive came into force. Now in 2024, the firsts companies will have to apply the rules.

Similarly in the USA, The Environmental, Social and Governance Law (2024) has changed the regulatory landscape. Where historically such reporting was voluntary, it has now become mandatory to make detailed sustainability reporting public knowledge.

Legislation like this is symptomatic of a wider trend towards transparency. Around the world, investors, pressure groups and the general public are increasingly vocal on environmental and social issues.

One of the problems legislation like this tries to address can be described as a “temporal mismatch” in carbon accounting. Consider a simple example like offsetting carbon emissions by planting trees. An organisation may calculate the number of trees, or square meters of woodland they need to plant to offset their carbon emissions. However, the carbon is being released today, while a tree might take 50 years to reach maturity before it begins to fully mitigate any emissions. There is a temporal misalignment here and that needs to be reflected in the carbon accounting and associated sustainability reporting.

The countries that signed up to the Paris Agreement committed to “pursue efforts to limit global warming to 1.5°C above pre-industrial levels.” Scientists tell us that to achieve this we need to reach net zero by 2050. While planting a tree today in 2024 is a fantastic idea and something we should all be doing, it’s 24 years too late to help us reach the target.

2. Adapt business models to unpredictable weather

Research by PricewaterhouseCoopers (Annual global CEO survey) found that 45% of CEOs believe their company will not be viable in ten years if it stays on its current path. The reasons for this existential threat are many and complex, but high among them is the need to adapt to a changing climate.

As Earth’s climate changes, the frequency of extreme weather phenomena is growing. 2023 was the hottest year since records began in 1850, and 2024 looks set to continue the trend. Already we’ve had the hottest January on record.

Manufacturing businesses are particularly vulnerable to the risks of extreme weather. This is partially because of the complexity of their supply chains. Manufacturing organisations have especially complex supply chains, often sourcing materials and components from vast global networks. Organisations operating a “just in time” policy, to reduce inventory costs, will be especially susceptible to disruptions.

The risk of losses and damages to businesses

In the UK, the Climate Change Committee (an independent, statutory body) highlights that the current risk of losses and damages to businesses from extreme weather is high. In 2003 a heat wave caused business losses of £400 – 500 million. By 2040, half of all summers are expected to reach that same level. Large parts of the country are also at risk of flooding and projections tell us this risk will increase unless there is an enhanced response from government and the private sector. Businesses in coastal areas face an additional risk from rising sea levels.

In the USA, the National Oceanic and Atmospheric Administration predicts that by 2050 the sea level will rise by as much as 12 inches and moderate flooding is expected 10 times more frequently than it occurs today. The same organisation has calculated that failing to curb emissions could result a disastrous 2-meter rise in sea levels by the end of the century.

Companies are having to calculate the risks they face and create mitigation strategies. This means adapting and evolving in line with the changing business environment.

3. Sustainability will increasingly be a priority for job seekers

Finding and retaining staff is a top priority for many CEOs in the tech sector. The skills gap in STEM industries has meant that job seekers with skills in high demand can afford to pick and choose their employers.

A study in the US found that 75% of millennials would be willing to take a pay cut to work for a responsible company. 88% said they would be more loyal to a company that helps them contribute to social and environmental issues and 64% wouldn’t consider a job offer from a company that doesn’t have strong CSR practices.

This is an issue that extends far beyond attracting the best staff, it’s also vital in retaining the people you’ve already got. Ever heard of climate quitting, also known as conscious quitting? That’s when staff leave an employer in favour of one with a better ESG record.

Former CEO of Unilever, Paul Polman is the co- author of “Net Positive: How Courageous Companies Thrive by Giving More Than They Take.” It’s a book that draws on his experiences as a CEO of one of the world’s most successful organisations. Polman gives many examples of how positive engagement with corporate social responsibility and sustainable business practices improves the bottom line for commercial organisations. During his time at Unilever, Polman presided over one of the company’s most successful periods. The Financial Times labeled him “a standout CEO of the past decade.”

Writing in Fortune.com, Polman tells us:

“Many [members of staff]have lost faith in politics to represent their views and secure their futures. They are turning to corporate power instead… millions of ordinary Americans (and others around the world) will want to know which side of the argument their CEO is on.”

4. Artificial intelligence will support sustainable manufacturing

For many of us, 2023 will be remembered as the year of Artificial Intelligence. It was the year we saw the introduction of large language models like Chat GPT.

The power of AI to analyse enormous data sets will certainly find increasing uses in the field of sustainability. Another study commissioned by PricewaterhouseCoopers in partnership with Microsoft predicts that AI for environmental applications could contribute 30 trillion USD to the global economy by 2030. It’s impossible to ignore numbers like that.

AI is a key enabling technology which could vastly improve energy efficiency and distribution. There are ethical considerations with AI, and many scientists remain skeptical. However, with shared responsibility and collaboration between the diverse stakeholders, there is potential for AI to play a transformational role in sustainable development.

One of the key strengths of Artificial Intelligence is its speed. AI enables rapid analysis of vast datasets for fast and accurate decision-making. As the global community grapples with sustainability issues, harnessing AI’s rapid capabilities will be paramount and time is in short supply.

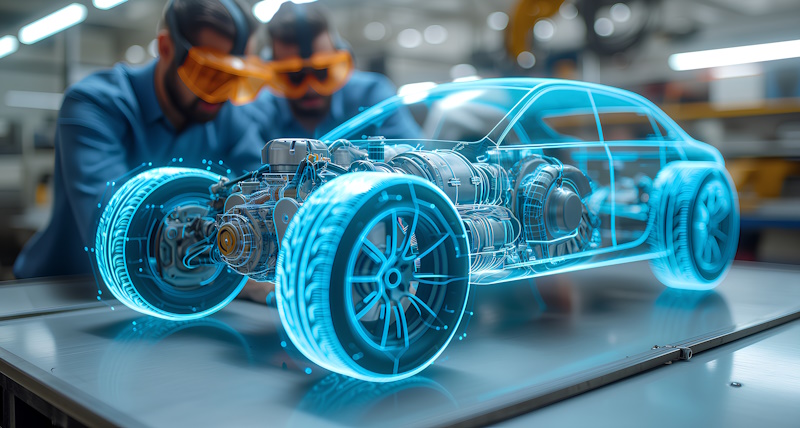

5. Advanced simulation software empowers eco-design

Product designers are under continual pressure to create more sustainable products. That might be designing more durable products with a longer lifespan. It might mean utilising more sustainable materials, or creating products that can be easily recycled, reused, or upgraded.

Whatever the design brief, advanced simulations can play an important role in facilitating sustainable design. Simulations and Computer Aided Engineering (CAE) help manufacturers optimise designs before physically creating a product. The process can identify opportunities to reduce the quantity of material used. This results in a lighter product that generates less waste and is easier to transport.

Lighter products, particularly in the automotive and aerospace sectors, can significantly reduce energy consumption. For instance, lighter vehicles require less energy to move, which can translate into improved fuel efficiency and reduced emissions.

By fine-tuning designs through simulation, manufacturers can reduce wastage and scrap, creating and testing early prototypes in a virtual space. Also, by using less material in the product, less waste is produced at the end of the product’s life, making recycling processes more manageable.

Advanced simulation software enables designers to simulate the entire lifetime of a product from design to end of life, anticipating potential problems, streamlining the product’s lifecycle and reducing the overall environmental impacts.

These are our 5 sustainabilty trends for 2024, but we want to hear from you. What sustainability trends do you foresee in 2024? Do you agree or disagree with us? Share this blog post with your networks and join the debate.

For quality that touches people's lives

Hexagon’s Manufacturing Intelligence blog is your go-to source for the latest manufacturing thinking. From expert commentary to industry perspectives, it’s designed to empower leaders and professionals to make smarter decisions, drive innovation and turn ideas into impact.