Model Based Engineering (MBE), otherwise known as Product and Manufacturing Information (PMI) or Model Based Definition (MBD) is simply digital tolerance annotations embedded in a CAD model. The idea is to remove both the paper and the interpretation from the manufacturing and quality processes. The types of information included are geometric dimensioning and tolerancing (GD&T), component level materials, assembly level bills of materials, engineering configurations and design intent.

With Computer-Aided Design (CAD) software tools, component manufacturers are able to receive a single CAD file and complete all the necessary steps to build and inspect a given part. The ability to design tooling, machinery and processes from the CAD model has been common practice for years, however, an accompanying blueprint was always required to create an inspection plan. Now the component datum structure, GD&T, key characteristics and any other necessary dimensioning can be embedded directly into the CAD model. The only thing a quality technician needs is inspection software capable of utilising the embedded data – like PC-DMIS.

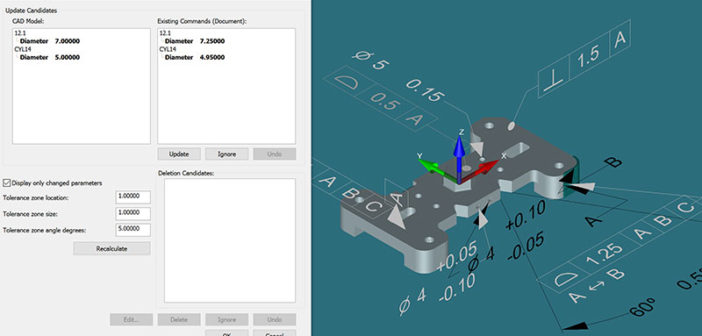

PC-DMIS can use this embedded data to create features, datum definitions and associated dimensions from a single click in the software. Another key point is the use of a feature control frame editor for the user interface. PC-DMIS all but eliminates the need to program inspection routines via messy code and clunky text editors.

By exploiting the benefits of MBE and PC-DMIS, a quality technician can create inspection plans for new components in half the normal time. It’s a simple process to import the CAD model and select the feature control frames and/or other linear dimensioning from the MBD. Either by automatically importing all PMI at the start, or individually selecting each dimension, PC-DMIS will add the correct features and tolerancing to the plan based on the designer’s intent with no interpretation necessary by the quality technician. As an added benefit, the built-in Change Manager also ensures the inspection routine is always up-to-date with the latest engineering revision changes and notations.