Visitors to the Hexagon stand at Formnext 2019 in Frankfurt will discover how the next generation of engineers are already making manufacturing smarter as part of the Formula Student competition to design and build a racing car.

Formula Student is where many of Europe’s top-flight engineering students get to display their know-how and project management skills. The competition is stiff, and through their universities’ industrial connections many of the teams deploy the latest cutting-edge solutions to design, build and inspect their vehicles, including technology from Hexagon’s Manufacturing Intelligence division and our growing 3D printing ecosystem.

At our stand in Hall 12.0 we’ll display a racing car built by the University of Paderborn’s Formula Student team that illustrates how engineers can exploit the unique capabilities of additive manufacturing and achieve track-ready quality as part of a complete process that goes from design and engineering right through to production and inspection.

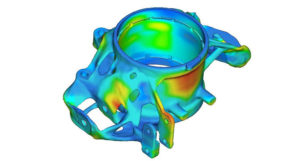

Visitors to our stand will be able to see how our innovative MSC Apex Generative Design software helped the team automatically optimise the lightweight design of the car’s polymer accelerator pedal and metal wheel carrier, before preparation for additive manufacturing using Digimat and MaterialCenter and Simufact Additive software respectively.

There will also be a demonstration of storing and managing additive manufacturing data with full traceability – a crucial feature that enables manufacturers to pinpoint the origin of any errors by tracking the production process from the material to CAD file through to printing.

We’ll print composite pedals directly on the stand and EDGECAM software will be ready to show how the wheel carrier is prepared in computer aided manufacturing (CAM) software for finishing. The Hexagon Inspire metrology software will complete the process by comparing the original CAD design and the finished part, which has been scanned by Hexagon’s Absolute Arm.

The benefits of additive manufacturing extend far beyond the automotive industry, of course, and we’ll also show what it can do for other sectors.

Visit Hexagon at stand B.79 in Hall 12.0 at Formnext 2019 from 19-22 November for answers to your design, manufacturing and quality questions for metals or composites, or email us at events@simufact.de to book your appointment.

Watch how Digimat-AM software simulates the build of a polymer accelerator pedal to avoid 3D print manufacturing issues: