Digital revolution is not an empty buzzword, it’s creating meaningful change in people’s lives. A shining example of this is patient-specific design. Once held back by high costs and manual manufacturing methods, today the patient-specific design industry is booming. In this blog, we examine its growth trajectory and the digital manufacturing tools that drive it.

Defining personalised medical devices

A personalised medical device is one with geometry, function or material selected to align with the needs of an individual. In general, personalised devices are intended to provide better performance and results for the patient than a one-size-fits-all device.

The International Medical Device Regulators Forum (IMRDF) defines three types of personalised medical devices. From least to most personalised, these include:

Adaptable

These medical devices are mass-produced and then adjusted at the point of care. An example of an adaptable medical device would be a limb prosthesis that can fit a wide range of patients.

Patient-matched

Medical devices in this category match a patient’s anatomy within a specific range established by the manufacturer. They may be designed with help from a healthcare professional, and are typically mass produced. Dental aligners are an example of patient-matched devices.

Patient-specific

These medical devices are intended to be used by one person only. They are designed to fit this person’s anatomy and often created in collaboration with a healthcare professional. Importantly, these devices are not mass produced. Examples include auricular splints, dentures, orthodontic appliances, orthotics and prostheses.

The path to growth in patient-specific design

Because patient-specific devices are not mass-produced, they have historically been significantly more expensive to manufacture than other medical devices.

However, with the emergence of additive manufacturing (AM) and software for 3D modelling, the patient-specific design industry is experiencing rapid growth, with the global healthcare additive manufacturing market expecting to reach $27.3 billion by 2030 with a very strong CAGR of 18.1%, according to a report by ResearchAndMarket.com.

Multiple reinforcing factors are driving this growth. AM makes it faster and easier to produce complex, patient-specific devices, and the broad accessibility of AM technology is increasing the number of patient-specific applications in healthcare. This in turn creates momentum for public and private investment in research and development for patient-specific devices as well as treatments and techniques that rely on 3D visualisation.

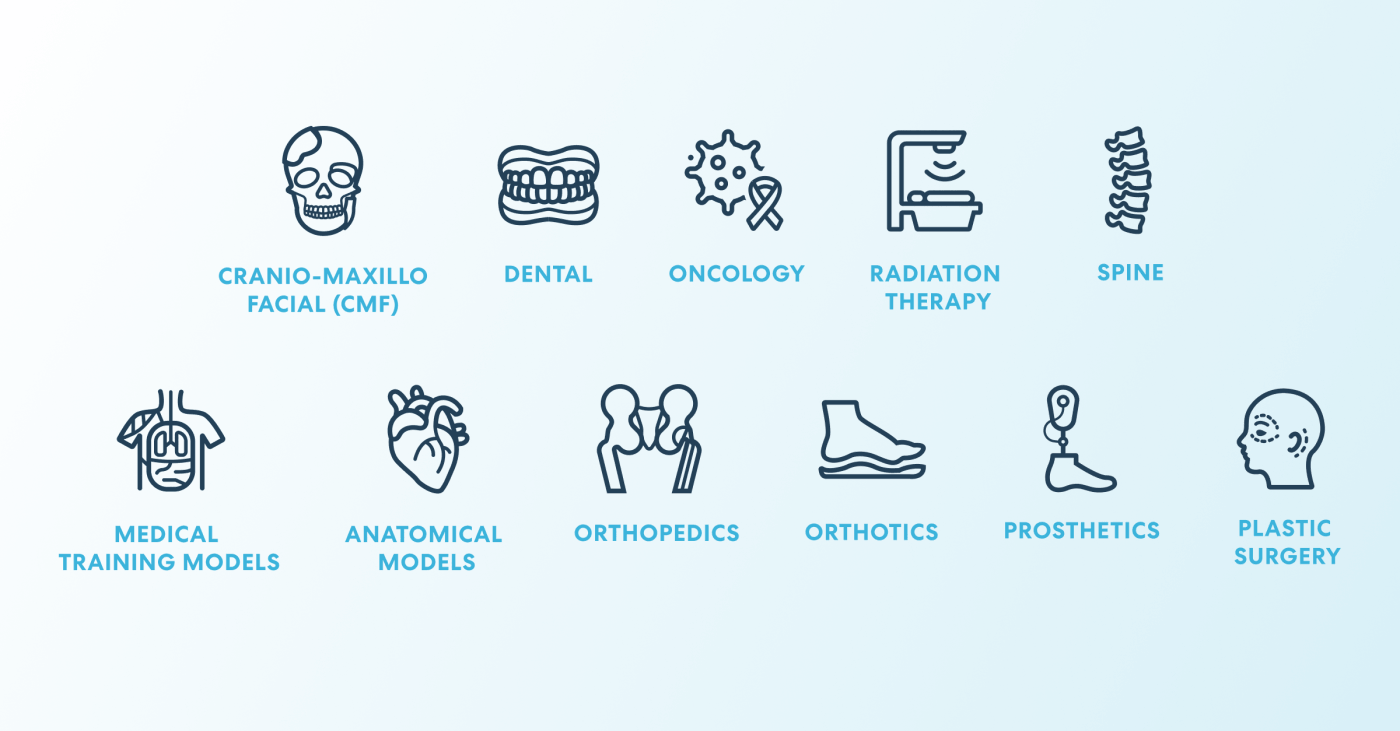

All of this increases demand for patient-specific design because it is becoming a technologically and economically viable choice in more instances. Examples include:

- cranio-maxillo facial (CMF)

- dental

- oncology

- radiation therapy

- spine

- orthopedics

- orthotics

- prosthetics

- anatomical models

- medical training models

- plastic surgery

The growing number of applications for patient-specific design is also fostering a rise in collaboration among medical professionals, product engineers and manufacturers. These relationships are contributing to increased growth in the sector as physicians better understand the capabilities of AM and 3D modeling software, and manufacturers better understand the design considerations for various types of patient-specific devices, treatments and techniques.

One challenge the industry faces, however, are regulatory requirements related to quality control. Regulatory frameworks are primarily designed for mass-produced devices, with testing criteria that are intended to be repeatable. Truly customised, patient-specific devices are, by definition, unique. Manufacturers may need to work with regulatory bodies to demonstrate that all possible iterations of a patient-specific design will meet all of the requirements for durability, performance and other factors.

Additive manufacturing and 3D visualisation software have made patient-specific design an economically and technologically viable choice in all the above instances.

Healthcare enters the digital age

Digital manufacturing workflows, with 3D printing and solutions for 3D medical design, have a critical role in the growth of patient-specific design. The significant advantages of patient-specific design – improved patient outcomes and reduced healthcare costs – mean that demand for these devices will expand in the future.