What is rapid tooling?

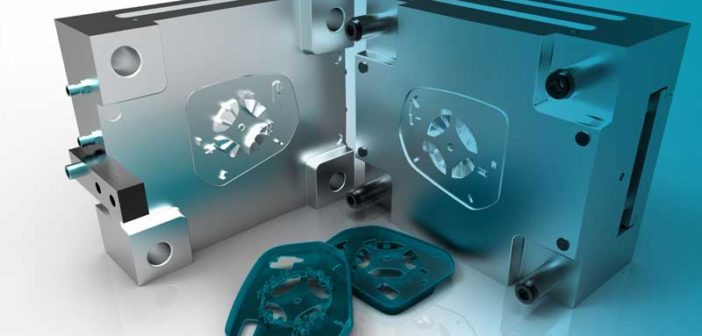

During the product development process, there is always a need to produce prototypes that can be used to test for function, assess design, evaluate concepts, and identify flaws. Rapid tooling combines rapid prototyping techniques with conventional tooling practices to offer a low-cost, highly efficient way of producing these prototypes, molds, and functional models.

There aretwo types of rapid tooling techniques: direct and indirect. The direct approach involves using rapid prototyping processes to create tooling inserts directly, while the indirect approach uses those same processes to create a pattern that will ultimately be used to create the tooling inserts.

What are the benefits of rapid tooling?

- Reduced lead-time. With traditional tooling methods, it can take months to create a working prototype for testing. With rapid tooling, that same object can be produced within a matter of days or weeks, which ultimately allows manufacturers to bring the final product to market more quickly.

- Cost-effective. Rapid tooling is significantly more affordable than conventional tooling practices. As such, adopting this approach makes multiple tests and trials feasible and allows manufacturers to keep final costslow.

- Test parts early. Because rapid tooling is a quick and low-cost process, working parts for testing can be produced very early on in the design process. This allows engineers to assess the product for function, flaws, design, and concept well before production – ultimately avoiding costly problems. By testing parts and designs at the beginning of product development, engineers can find defects and correct them when they are the least expensive and easiest to fix.

How rapid tooling is transforming manufacturing processes

Rapid tooling is optimizing manufacturing processes by enabling highly efficient and precise prototyping. Using conventional methods, it’s prohibitively expensive and time-consuming to create high-quality prototypes for as many tests as necessary to confirm that a product is ready for production. In addition, it’s not always feasible to use materials that allow for functional testing.

With rapid tooling, manufacturers can create ultra-precise molds and functional models with ease. This streamlines the manufacturing process, allowscompanies to innovate and improve their products with ease, and ensures that manufacturers only produce precise, high-quality parts.