Without regular calibration, the most accurate and precise CMM in the world can quickly become little more than a random number generator. There would be no way of telling if a measurement device is reading the correct value. In this blog, we’ll explain the key concepts and ask what’s the risk of skipping calibration.

Want to know how to stay ahead of compliance risks and equipment failures? Read on.

Calibrations are more than just an accuracy check

Calibrations are more than just an accuracy check Calibration is more than just a technical requirement. It’s a vital process that ensures compliance, guarantees precision, and protects businesses from costly mistakes. Whether you’re managing portable tools used in diverse environments or operating high-precision stationary systems, regular calibration safeguards your operations from inaccuracies, audit risks, and unexpected downtime.

So, what happens if you don’t calibrate your equipment on time? Poor measurement accuracy can have cascading effects, from scrapped parts to failed customer audits. This blog dives into why calibrations matter, when to schedule them, and how to keep your equipment in optimal condition.

Why calibration matters?

Calibration is the backbone of reliable measurements, but its significance goes far beyond ensuring accuracy.

For stationary systems (e.g., CMMs)

Stationary systems play a critical role in industries where precise measurement is essential. Regular calibration ensures:

- Measurement consistency across various part geometries and volumes

- Reliability in quality control, aiding in audits and internal systems.

- Conformance to recognised standards such as B89 or ISO 10360, depending on the customer’s selected process

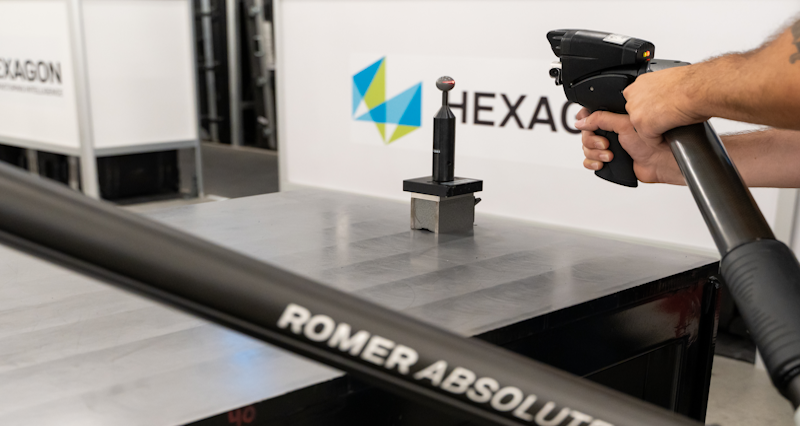

For portable devices (e.g., Absolute Arms)

For handheld or mobile measuring tools used in dynamic environments, regular calibration is equally important:

- Ensure measurement traceability

- Maintain repeatability and confidence in results

- Align with OEM specifications and preserve device integrity

At its core, calibration establishes traceability and repeatability, both of which are essential for passing through audits and maintaining internal quality systems.

When should you get calibrated?

The recommended timing for calibrations or certifications is typically once a year, but can vary depending on your equipment type, usage intensity, and environmental factors. Here’s a general guide:

- After major maintenance or relocation

- Following interim inspection issues

- Annually, as standard best practice

- Upon initial installation for stationary systems, to validate accuracy

How to know when you’re due

Wondering how to tell if your equipment is overdue for calibration outside of the regular annual cadence? Beyond checking the sticker on your device, these indicators can serve as warning signs:

- Decreased measurement repeatability. Repeat measurements produce inconsistent results even under controlled conditions.

- Operator or SPC (statistical process control) flags. Issues raised during day-to-day operations or quality inspections.

- Failures during interim inspections. Issues detected during interim checks or visual wear-related signs.

- Documentation gaps. Missing valid calibration certificates during pre-audit reviews.

Regular monitoring and documenting of performance trends can help identify the optimal timing for calibration.

What happens if you don’t calibrate?

Neglecting calibration comes with high stakes. Here’s what’s at risk:

- Bad data leads to costly outcomes: Drift in measurements may result in defects, reworking, material waste, or rejected shipments.

- Audit and compliance issues: Expired or missing certifications can flag audits and compromise contracts.

- Unscheduled downtime: Undetected wear leads to system failures, halting critical operations.

- Compounding costs: If calibration lapses are discovered in the middle of a production run or contract, the financial impact multiplies.

Investing in regular calibration is a straightforward way to avoid these cascading issues.

What’s involved in calibration?

The calibration process isn’t just about measurement adjustments; it often includes preventive maintenance to ensure lasting accuracy.

Stationary systems

- Follows established standards

- Uses test artifacts like step gauges or lasers to verify system accuracy

- Includes interim performance checks to correct drift

Portable devices

- Includes preventive maintenance such as cleaning, stylus replacement, and inspection of wear-prone parts

- Calibrated to OEM specifications, with traceable results and audit-ready documentation

Working with an accredited provider like Hexagon ensures precision and traceability throughout the process.

Proactive steps to reduce risk

Maintaining an effective calibration schedule can save your business from compliance risks and unexpected costs. Here’s how to stay ahead:

- Set up regular service schedules.

- Choose a trusted partner like Hexagon—an ISO/IEC 17025-accredited organisation—for calibrations performed to rigorous standards, with audit-ready documentation available whether you require accredited or standard services.

- Use interim checks and environmental monitoring based on your setup—whether in a controlled lab or on a shop floor

By focusing on proactive measures, you can extend the lifespan of your equipment and maintain confidence in your operations.

Calibrations protect compliance and operational integrity

Calibration isn’t just an operational step; it’s a shield for your business against otherwise avoidable rework, downtime, and audit risks. Whether it’s portable tools or stationary systems, maintaining routine calibrations ensures measurement accuracy, protects profitability, and fosters compliance.

Don’t wait for a missed calibration to disrupt your workflow. Reach out to Hexagon’s team today for expert guidance and ISO-certified services that keep your equipment running smoothly. Contact us for more information.