Albert Einstein put it best when he said, “Out of clutter, find simplicity. From discord, find harmony. In the middle of difficulty lies opportunity.” For Hexagon Manufacturing Intelligence, this means identifying the challenges that manufacturers struggle with each day and providing simple solutions that improve their overall efficiency. One aspect of our business that we are always looking to improve the overall experience for our customers when using our products. So, when the Capstone Director from the University of Rhode Island (URI) Department of Computer Science and Electrical Engineering reached out to us to sponsor Capstone, we had the perfect idea for a project. With a fresh look and using latest toolsets, our sponsored students were able to analyze our software for efficiency during different modes of use and implement working models to demonstrate those improvements. A new Capstone project was born and named, Workflow Optimization for Industrial Software Applications.

Hexagon and URI hold a strong relationship and regularly look for ways to cooperate with each other. Each year, URI seeks out company sponsors through its Capstone Design Program to initiate projects that give students real industry experience in exchange for project work for the company. URI’s College of Engineering is a diverse community of scholars, learners, and professional staff dedicated to the development and application of advanced technologies, and working together to enhance quality of life for all.

The Students’ Challenge

This year, the challenge was twofold. First, we tasked the students with investigating the workflows for various applications in our existing software portfolio. The second task was to design new interfaces that could reduce the number of steps, or otherwise simplify the implementation, of solutions through the software.

In quality inspection, the software used needs to be able to collect large amounts of measurement data, analyze that data and then enable the manufacturing process to act on it. This software must be flexible enough for engineers to implement customized CNC controlled data sampling strategies and analysis reports, while still easy enough for operators to use in a manufacturing setting. Therefore, the software has at least two main modes of use: engineering mode and operator mode. In addition to having these two modes of use, the software must also be versatile enough for use on multiple measuring system platforms that utilize a wide range of sensor types and support the analysis and reporting requirements for different key industries.

In quality inspection, the software used needs to be able to collect large amounts of measurement data, analyze that data and then enable the manufacturing process to act on it. This software must be flexible enough for engineers to implement customized CNC controlled data sampling strategies and analysis reports, while still easy enough for operators to use in a manufacturing setting. Therefore, the software has at least two main modes of use: engineering mode and operator mode. In addition to having these two modes of use, the software must also be versatile enough for use on multiple measuring system platforms that utilize a wide range of sensor types and support the analysis and reporting requirements for different key industries.

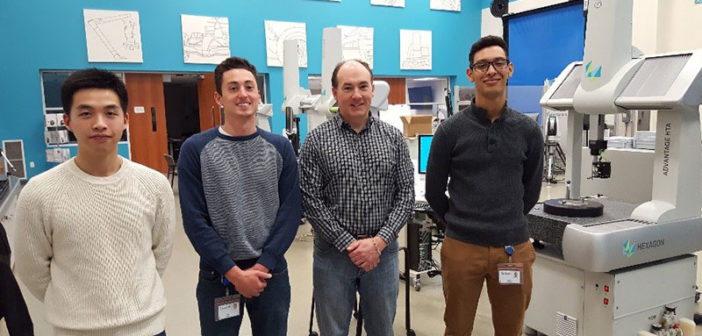

The research project investigated the workflows needed for several key applications and tested the implementation using existing software products. Existing software products include PC-DMIS, QUINDOS and several others found in related areas, for example CAD/CAM software, in addition to metrology software. With Technical Director, Jonathan O’Hare from Hexagon, and their own version of PC-DMIS in hand, the students had everything they needed to evaluate the software workflows.

The Big Take-Away

The Capstone project lasted two semesters, running from September 2016 to May 2017. Their research found that the best outcome for this project was a redesigned example of a GUI (Graphical User Interphase), targeting three segments in PC-DMIS of the students choosing (Probe Qualification, Menu Bar and Redefined Data Structure). This new GUI would be more efficient and easier to use. The goal was to reduce the average learning time of 6-12 months per user by having the user complete fewer tasks to finish a process, and to provide a visible workflow that can be followed step by step.

The Capstone project lasted two semesters, running from September 2016 to May 2017. Their research found that the best outcome for this project was a redesigned example of a GUI (Graphical User Interphase), targeting three segments in PC-DMIS of the students choosing (Probe Qualification, Menu Bar and Redefined Data Structure). This new GUI would be more efficient and easier to use. The goal was to reduce the average learning time of 6-12 months per user by having the user complete fewer tasks to finish a process, and to provide a visible workflow that can be followed step by step.

Each of the students took on a portion of the project to develop the GUI in three areas: Menu Bar, Probe Qualification Process and the Refined Data Structure. This included making each portion in PC-DMIS more efficient and more appealing to the user. After working on the individual portions, they combined these portions using the Menu Bar GUI as their base for adding the two other portions. This allowed for a much more efficient workflow.

The proposals made by the students are now under review with Hexagon’s software engineering department. While the designs that the students implemented were only proof-of-concept, the concept changes from our current software will likely be adopted in stages over the course of the next couple of years.

Looking To The Future

The challenges that manufacturers face today offer opportunities for prospecting technical engineers tomorrow. By giving these students an inside look into how companies are shifting towards smarter technology, they will have a better understanding of how to solve these challenges in the future. With a commitment to the development and application of advanced technologies, the University of Rhode Island is well on its way to molding the minds of our future.

To learn more about this Capstone project and URI’s Department of Engineering, check out the Workflow Optimization for Industrial Software Applications Capstone project page.