At this year’s Hannover Messe, more than 4,000 exhibitors took the opportunity to present their latest technologies to the 130,000 visitors walking the aisles at this key industry event.

It was great to see such a pivotal exhibition back in a completely physical capacity, enabling people to get hands-on with demonstrations covering focus areas such as artificial intelligence, hydrogen, energy management, connected and intelligent production solutions.

One of the strongest benefits of a physical event is the nurturing of relationships and collaboration. This was also a powerful theme during the opening ceremony, which proved to be a sensational celebration of the partner country for 2023, Indonesia, one of the world’s most populous countries. During the ceremony, the President of Indonesia, Joko Widodo, emphasised the need for strong global industrial alliances and the enormous mutual benefits for those who choose to do so with countries in South East Asia, such as Indonesia.

Here is ZVEI President and Chairman of Hannover Messe Exhibitor Advisory Board, Dr Gunther Kegel’s view of the main themes this year: “Electrification, digitisation and automation: these three trends have shaped this year’s Hannover Messe and are already leading to solutions for achieving effective climate protection. And it is precisely the interplay of these trends that demonstrate that the energy turnaround must also usher in a turnaround in energy efficiency.”

This is a very good assessment, but here are my take-aways from Hannover:

Reaching for the cloud

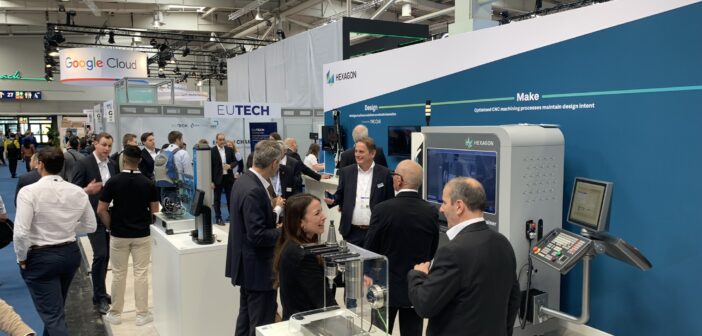

Walking the halls at Hannover Messe 2023, particularly in Hall 17 with Microsoft, Google and Amazon taking large areas of floorspace, it was evident that there is an accelerating shift to the industrial cloud. The benefits of this are clear: greater speed, efficiency and flexibility.

Leading from the front in this space is Hexagon, with the recently-launched Nexus software platform (which has been co-engineered with Microsoft). The completely open cloud-based platform allows manufacturers to connect Hexagon and third-party tools to enable real-time collaboration and feedback between engineering and manufacturing in a way that has never before been achieved.

The power of digitalisation

This is a hugely exciting time in manufacturing where we’re starting to see new tools such as Nexus really open the door to new possibilities and harness the true power of digitalisation.

One of the areas digitalisation is having the greatest impact is with the breaking down of traditional manufacturing operational silos. Nexus is set to be a game-changer here; enhancing cross-discipline collaboration and visibility to remove previously ever-present bottlenecks.

Combined with intelligent automated processes, manufacturers have a far greater ability to not only increase production speeds, but also to scale their manufacturing.

Let robots do the hard work

Robots, automation and AI are big news currently, so it was not a surprise to see this so evident at Hannover. Voice-controlled robots utilising AI, collaborative cobots capable of taking ever-greater payloads with more and more precision. It’s incredible to see.

On Hexagon’s stand at Hannover Messe we welcomed our robotic dog, Ava, featuring the BLK ARC sensor. And there was another example of how we’re helping to dismantle silos, scale production and supercharge time-to-market; the new automated inspection cell, PRESTO. Launched at the show, PRESTO empowers makers with reduced quality inspection times (of up to 50%), increased efficiency, and streamlined workflows.

The key to PRESTO is simplicity. Programmed with intuitive built-in workflows, PRESTO is accessible for users who are non-experts in robotics and metrology, and this goes a long way to helping to overcome issues related to skills shortages, which impacts all areas of manufacturing.

Sustainability top of the agenda

There was a notable spirit of positive change at Hannover Messe 2023. During the opening ceremony, speeches pressed home the need for collaborative partnerships to establish digital technologies for the benefit of people and planet. In the drive to limit climate change, digital technologies in manufacturing will be key to ensuring energy and materials are not wasted and a positive cross-pollination of ideas and technologies will make this objective achievable far quicker. On the booths at the show, there was a raft of climate-neutral digital production solutions and new hydrogen technologies revealed by startups and established companies alike.

On the Hexagon stand during Hannover Messe, a panel discussion (pictured above) was held on the subject of “Building a sustainable future of manufacturing”. The panellists included Frederic Vetil, Director of Digital Transformation – Manufacturing 4.0 at Safran Group, Audrey Colle, GM, Cloud for Manufacturing and VP of Sustainability at Microsoft, and Ole Geisen, Head of Engineering Services for Additive Manufacturing at Siemens Energy, alongside Hexagon’s Manufacturing Intelligence division’s Director of Sustainability ESG, Marion Rouzeaud. More on the topics covered in this session to come very soon!

A busy exhibition schedule

Hannover Messe was a wonderful celebration of how manufacturing industries are taking huge steps towards much greater control over their processes through digital technology. You can read more about our presence at Hannover Messe 2023 by reading our blog Hannover Messe opens in ‘time of change’. The collision and convergence of technologies is creating some incredibly exciting solutions, and I can’t wait to see further developments next year.

We are definitely in exhibition season now, so hot on the heels of Hannover Messe, I’ll be travelling to Stuttgart for the Control show. For more information on our presence there, click HERE

I’ll report on this exhibition in the next blog, but check out this preview video of the awesome metrology solutions we’ll be showcasing there: