Environmental regulation is putting fresh pressure on the automotive sector to pursue further innovation in lightweighting. In mid-January the EU confirmed new CO2 emission standards, which require emissions from cars to be on average 37.5% lower in 2030 than in 2021. For light vans the figure is 31%. China and the US are also looking at new, more stringent emission goals.

Greater uptake of zero-emission electric and lower emission hybrid vehicles will help theindustry attain its sustainability targets. But electric vehicles have their own weight problem. The distance an electric vehicle can cover before recharging is an important criterion for electric vehicle customers. Yet an electric vehicle’s powertrain, including integrated battery, is typically heavier than one for a combustion engine vehicle – and every extra kilo counts when it comes to fuel efficiency or extending driving range.

The car industry has already innovated extensively in lightweighting, including in the use of aluminium alloys. But whatever a customer’s choice of engine, automotive manufacturers will need to go farther, whether it’s by introducing plastic in the powertrain, or carbon composites in the body, chassis and interiors; or creating new, less dense, yet very strong structures.

Fortunately, technology is making it simpler and more cost-effective to do so, and analysts predict strong growth in both additive manufacturing and composite use.

The US research company SmartTech expects the total market for automotive additive manufacturing to grow from

$1 973 million in 2019 to $6 658 million by 2024 as its use expands from prototyping to mass, customised part production.

BCC Research meanwhile estimates that the global market for automotive composites will be worth £7.3 billion by 2022, up from £3.8 in 2017.

Brian Shepherd, our Senior Vice President Software Solutions, explained at Hexagon’s annual HxGN LIVE 2018 conference how we worked with partners to halve the weight of a car hood’s hinge using additive manufacturing.

But composites are complex, and it’s important to reduce costly waste and increase productivity by modelling in advance the manufacturing process, and virtuallytesting the finished composite material’s performance.

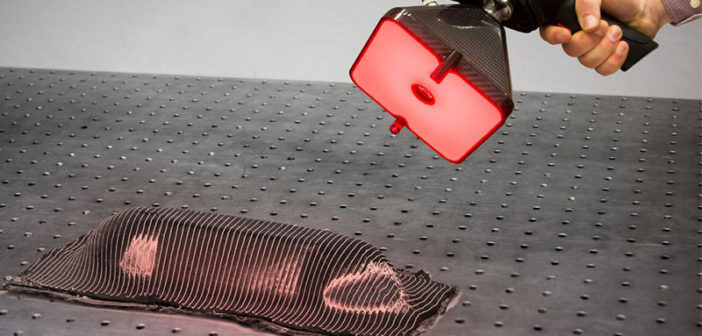

Manufacturers use Hexagon Manufacturing Intelligence’s composite inspection solutions, for example, to perform detailed surface mapping of carbon fibre parts and create 3D fibre orientation measurements. And our Digimat software enables companies to speed up the design and development of high-performance composite parts by combining process simulation with structural finite element analysis (FEA).

We don’t stop there. Whatever our automotive manufacturing customers’ future mobility strategy, our products help them use composites and additive manufacturing to make it sustainable.