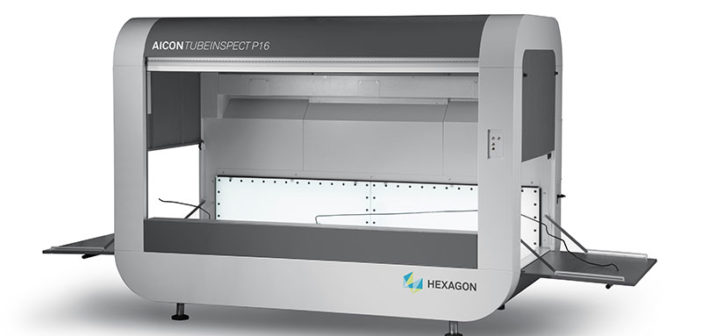

A good two years after the P series’ launch of the optical tube and wire measuring system AICON TubeInspect, AICON gives a very positive summary. The new AICON TubeInspect P8 and P16 are real bestsellers!

The systems are equipped with latest camera and LED illumination technology as well as a highly precise and long-term stable glass reference. They replace expensive mechanical gauges, are insensitive to vibrations and thus applicable in production environment.

Already today, TubeInspect P8 and P16 meet Industry 4.0 requirements. The systems can be linked to all renowned CNC bending machines. Adjustments and corrections are directly transmitted to the bending machine.

Günter Suilmann, Director Global Sales TubeInspect, boils it down: “The new P series meets the customers’ requirements at the right time. To increase efficiency, it is mandatory for suppliers to spare gauges. Additionally, Industry 4.0 requires connected production for the adjustments of machines. TubeInspect offers both!”

Proton Engineering in Southern Sweden was one of the first AICON TubeInspect P16 customers. The company is completely content. “It is another step towards providing the right quality to our customers. Our production becomes even more cost-effective, which also benefits our customers”, says Fredrik Ottosson, CEO at Proton Engineering.