Did you know that 2022 was the 50th anniversary of the sustainability movement? Back in 1972 a group of climate scientists working for the Massachusetts Institute of Technology predicted the current climate crisis in an article for the academic journal Nature.

At the time, Nature described the study as “another whiff of doomsday”. Nowadays, these early pioneers have been validated. The World Economic Forum recently reported on a study suggesting a 2% increase in global temperatures could displace 3.5 billion people. That’s just short of half the global population.

But every prediction contains the word “if”, even when it’s not actually stated it’s implied. There is room for optimism because fixing problems and improving the world are deeply human characteristics. The instinct to expand our horizons and shape the environment around us will never stop, but we need to change the way we do it.

For a long time, we thought that humans were the only species to make and use tools to improve their standard of living. Now we know of a great many other species that do the same, but we are the only one that uses them to produce other, more advanced tools. Perhaps Homo Sapiens is no longer the right name for our species? Perhaps, with the forth industrial revolution, we are also Homo Factorem (Man the maker)?

What happens when Homo Sapiens meets Homo Factorem? The makers of the world rise to the challenge with the tools they need to make better products in new ways. They bring their ideas to life faster, harnessing their intelligence to find greater efficiencies with lower environmental impact. When you think about it like that, Smart Manufacturing and sustainability go hand in hand.

In this blog I’ll discuss some of the ways that smart manufacturing is changing the industrial landscape and helping companies achieve their sustainability goals.

Sustainability, like smart manufacturing, begins with data

Smart manufacturing, when you strip away the buzzwords and the layers of complexity, is about collecting and sharing information in new ways. With that information we create new technologies and new ways of working that improve the manufacturing process.

Sustainability, like smart manufacturing, begins with data. It begins with knowledge and understanding, because, to quote an old saying in metrology, “What you can’t measure, you can’t improve”. To reduce your environmental impact, you must first know what your impact actually is. Smart manufacturing makes resource utilisation clear because of the data it collects.

Efficient use of resources is one of the fundamental aspects of smart manufacturing. For example, digital twin technology reduces or even eliminates the need for physical testing.

Simulations are so accurate and precise, so realistic, that a virtual recreation is sufficient and, in many cases, preferable. Just think about the financial savings in areas like vehicle crash testing, and the safety benefits of aeroplane test flights. Design for sustainability with engineering simulations is a subject we discussed in detail elsewhere on the manufacturing intelligence blog, but a recent project in France has taken the idea a step further.

The NCSIMUL team have recently created HxGN Machine Trainer, a CNC and coordinate measuring machine simulator that offers a new way to train staff at a much lower cost. There are no raw materials involved, no machine downtime and no risk of damage.

This is just one of many examples showing how smart digital solutions can reduce the way we use resources. Another is by using artificial intelligence to create a more efficient schedule of machine maintenance. The purpose of predictive maintenance is to forecast the next likely failure and then schedule repairs to prevent it before it happens. This means that companies can address issues before they become serious problems, save machine down time, improve efficiency and extend the lifetime of the equipment.

Sustainable products are designed with this in mind…

Digital twin technology means you can test all sorts of design variations with zero environmental impact. For a product or a process to be truly sustainable, it needs to be designed with these issues in mind. Designers need to consider everything from the raw material use through to the ways the product can be recycled. It means taking a full product lifecycle approach, optimising throughout the value chain.

Smart manufacturing approaches use artificial intelligence to create multiple design iterations in search of the most sustainable. They reduce material usage without compromising the strength or durability of the finished product.

How smart manufacturing delivers sustainability

- Utilise resources more efficiently and boost plant efficiency

- Use AI to improve product and process design

- Empower your staff with connected data

- Advanced simulations provide better training opportunities and reduce or eliminate physical testing

- Create instantaneous feedback loops throughout the product lifecycle

- Smart manufacturing does not replace people, it empowers them

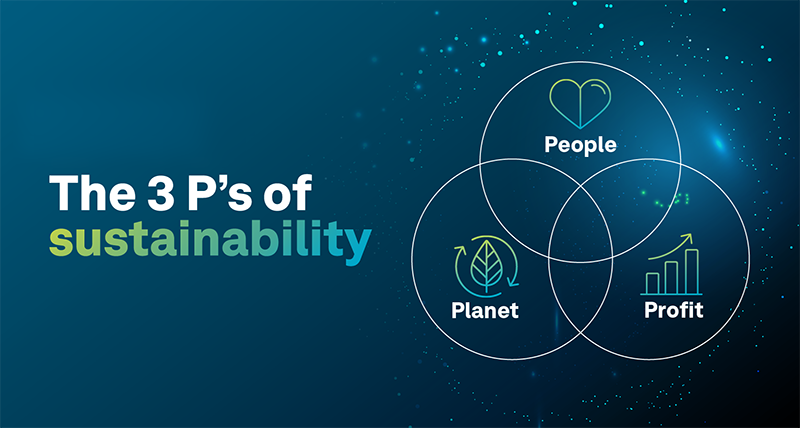

Sustainability is more than environmental and economic. A great way to break down the idea is through the triple bottom line model. This is a sustainability framework which asserts that long term success requires a three-fold approach. It’s also known as the 3 P’s of sustainability, these are Planet (environmental sustainability), Profit (economic sustainability) and People (wider social responsibility). All three have an equal importance.

The 3 Ps of sustainability, also known as the Triple Bottom Line, was first described by sustainability consultant John Elkington in 1994

The people element is absolutely vital, but in terms of smart manufacturing it would be easy to overlook. Afterall, key themes in smart manufacturing are automation, robotics, artificial intelligence and machine learning. Human beings are often dismissed as little more than a source of error, but we must not ignore the human element of either sustainability or smart manufacturing. To do so would be to deny us two of our greatest assets in the search for solutions: creativity and empathy. All businesses are human businesses. All customers are people.

People are the reason that manufactured goods exist in the first place, so manufacturing has to turn on the head of a pin and become the solution.

For me, that’s the important take away. Smart manufacturing should never remove people from the mix, it should empower them. That’s what it will take for sustainability to become a true success.

We’ve previously written about how automation can help deliver sustainability and how generative design is a key enabler for efficiency and sustainability, but what are your thoughts on the topic?

Share this post with your social networks and join the conversation or contact us directly to find out how our smart digital solutions can help with your sustainability goals.