Customers are increasingly concerned about the environmental impact of their choices– as are industry regulators. Yet at the same time people often base their final purchasing decisions on price. So, it should come as no surprise that many manufacturers struggle to juggle immediate cost and productivity constraints with their longer-term sustainability objectives.

Recent advances in integrated computational materials engineering (ICME), however are making it much easier to design and produce goods that combine greater sustainability with cost-effectiveness and manufacturing efficiency.

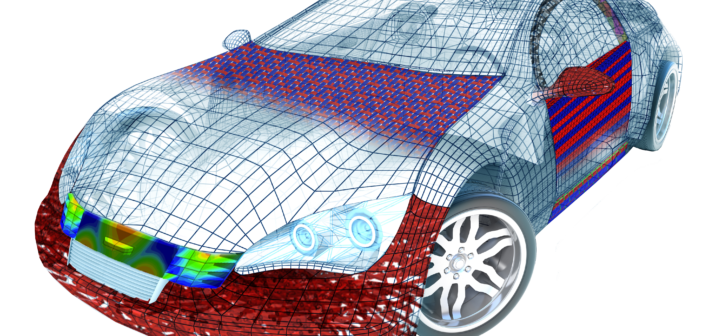

A manufacturer’s choice of materials has an enormous impact on both a product’s overall cost and its environmental impact throughout its lifetime. Recognising the critical role that a material’s properties play in product performance, ICME draws on models and software tools to put materials at the centre of product design and engineering. For example, with ICME, companies can engineer products that fully exploit a given composite’s performance to reduce waste during manufacturing. By using ICME manufacturers can remove the need for physical prototyping, further decreasing the consumption of material. Another key benefit of ICME is it can reduce the weight of components by as much as 20% on top of traditional approaches, while ensuring their strength and making them less prone to failure, resulting in products that are more energy efficient and durable. ICME also helps manufacturers adhere to safety and sustainability regulations.

So, given the advantages of ICME and the fact that the discipline has been around for decades, why aren’t more manufacturers using it? The answer is that up until very recently adopting ICME was dissuasively expensive and time-consuming. As a result, its use has been restricted to a few industries such as aerospace and automotive, where manufacturers are under pressure to increase vehicle fuel efficiency using new, lightweight composite materials.

Determined to help more of our customers across all sectors gain a business advantage from developing and using new materials, we have spent the last 17 years working with leading academic researchers to crack the problem of how to make ICME much more accessible, affordable and easier to use. The result is Hexagon’s 10xICME.

Smarter use of data

One of the biggest obstacles to widespread and affordable ICME use has long been data management. Efficient, cost-effective ICME depends on seamlessly integrating accurate information from materials engineering into product design and manufacturing solutions.

10xICME is the first ICME solution to overcome the challenge of secure data management so that manufacturers can tap into a consistent and trustworthy source of data about materials across the whole supply chain and embed a digital twin of the material from the supplier’s material card through manufacturing to the final part. Without an effective and reliable data management system, it is easy for teams using different systems to lose vital test information. To be efficient, the material lifecycle management must make it possible to combine the use of virtual data from simulation systems with physical material tests, CT scans and metrology data, without any risk of information loss.

Being able to efficiently use the materials data generated by powerful simulation tools plays an important role in making design and engineering more sustainable, including material selection. Typically, once engineers hit upon a design for a material, they produce and physically test multiple samples. By using computer simulation to virtually test materials, engineers not only capture a full analysis of the performance limits of an advanced material, they also reduce the need to produce multiple physical test samples. For example, the Camanho model enables aerospace composite performance to be accurately predicted from coupon to part. This gives engineers greater trust in performance predictions as advanced composites aren’t treated as “black metal”. Using material lifecycle management, they can work with materials specialists to review the correlation of physical and virtual tests and apply those safety margins to their designs to reduce material use.

ICME solutions also take into consideration how manufacturing processes impact the unique properties and performance limits of each material. Armed with this information manufacturers can optimise designs to use the minimum amount of material needed, thereby reducing waste.

These are just a few examples of the many ways 10xICME makes innovation in materials compatible with sustainability and better design and manufacturing. Read our ICME white paper to find out more.