Not every manufacturing process starts with an abstract design; sometimes we have to work backwards, putting a complete part at the very beginning of our own design process. Taking an existing part and analysing it in detail so it can be perfectly recreated or integrated into a new system is what reverse engineering is all about, and it’s a process that’s more and more in demand. And that’s a demand on which Hexagon Manufacturing Intelligence can deliver with speed and precision by putting together a ROMER Absolute Arm with Integrated Scanner and VISI, the leading CAD CAM solution from Vero Software, to create a complete non-contact reverse engineering system.

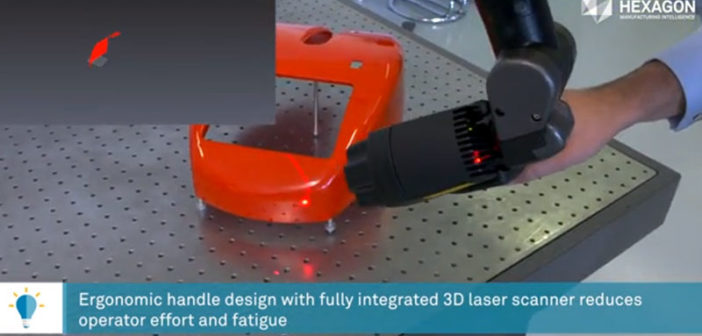

The advanced RS4 3D laser scanning technology of the ROMER Absolute Arm range makes digitisation simple, even on shiny and complex plastic surfaces. Once the portable measuring arm and laser scanner combination has been used to create a complete CAD model of the part, this can be used to develop the moulds needed to recreate the part. This process can be carried out completely within VISI using industry standard moulding components. The software can even virtually simulate the manufacturing process to identify potential moulding issues in advance and avoid resource wastage, as well as defining the toolpath data needed to run the CNC machine that will create the part.

Take a look at our video walkthrough to see how it all works, from physical to virtual and back again.