Expensive and complicated production processes associated with patient-specific medical devices presented a major obstacle to the wider adoption of this approach for a long time. Digital manufacturing has changed that. 3D printing, 3D scanning and software for organic 3D design have improved the efficiency and speed of patient-specific design. These technologies have also enabled the consolidation of the patient-specific design workflow into a streamlined process.

The outcome: a rapid rise of patient-specific design.

In this article, we dive into this exciting area. We examine the digital tools that play a central role in patient-specific design and healthcare, their place in the workflows, and developments on the horizon.

1. Data collection

With respect to patient-specific design, data collection refers to acquiring data about the patient’s anatomy or physiology through medical imaging and 3D scanning.

Medical Imaging

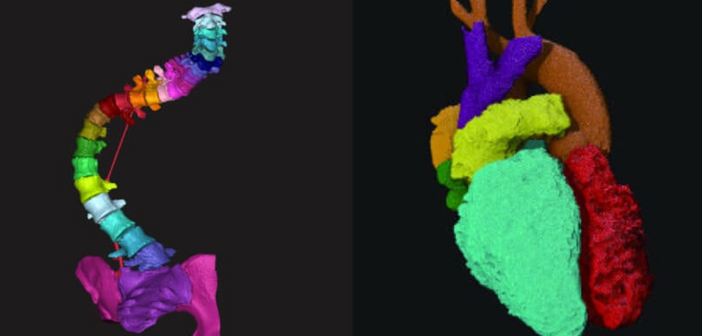

Medical image segmentation is essential for creating the accurate 3D models that allow physicians to perform surgical planning, create patient-specific product designs, recognise complex patterns or isolate regions of interest.

These 3D models are generated from CT or MRI scans and provide detailed information about the patient’s bone structure, joint anatomy, and other relevant features. This allows the patient-specific instrumentation to be customised to the individual patient’s anatomy.

The 3D models are then used to plan the surgical procedure and design patient-specific instruments, such as cutting guides and jigs.

Medical imaging software can analyse the 3D data to determine the optimal positioning and alignment of surgical components, which is then used to manufacture the customised instrumentation.

3D Scanning

3D scanning is becoming a more popular option for data collection in patient-specific design applications. It enables you to accurately measure a patient’s body shape, size and surface area, as well as individual outer body parts.

Scanners bring speed, precision and safety to personalised data collection, allowing medical professionals to streamline processes. You can perform a complete body scan with a stationary or handheld scanner, and the data can be brought into a 3D visualisation platform to begin the modelling process.

3D scanning also makes it much easier to monitor changes in a patient’s body over time as well as compare pre- and post-op data. For outer body applications of patient-specific design, such as back braces and prostheses, 3D scanning is helping to improve efficiency and accessibility.

2. Augmented Reality & Virtual Reality

Augmented reality (AR) and virtual reality (VR) are becoming more frequently used at the outset of patient-specific workflows to better understand the patient’s anatomy for surgical planning and education.

While printing 3D anatomical models can be helpful, they do require an investment in expertise, equipment and time. This could potentially make the process too costly and limit its accessibility.

Using AR and VR can extend the benefits of 3D modelling to more patients through advanced visualisation. For example, with the right AR and VR capabilities, it’s possible to instantly realize a patient’s CT scan in 3D, so physicians can examine the details of the patient’s anatomy, and plan surgery.

3. Digital 3D design tools

Digital 3D design tools are empowering the creation of highly personalised medical solutions that are tailored to individual patient needs, leading to improved comfort, functionality, and clinical outcomes. They achieve this by:

a. Leveraging patient data

Digital design tools can integrate patient-specific data from medical imaging like CT and MRI scans to create personalised 3D models of anatomy. This allows for the design of medical devices, implants, and surgical guides tailored to a patient’s unique anatomy.

b. Enabling on-demand manufacturing

The combination of digital design and 3D printing allows for on-demand manufacturing of patient-specific medical devices and implants, reducing the need for large inventories and ensuring availability when required.

c. Accelerating development

Healthcare providers can test and refine patient-specific designs using rapid prototyping. This allows them to iterate fast, reduce the development cycle and quickly provide solutions.

d. Enabling customisation

Digital tools allow for easy customisation in healthcare, leading to better outcomes compared to one-size-fits-all solutions.

e. Improving surgical planning

Surgeons can use patient-specific 3D printed anatomical models created from digital design to plan complex procedures, practice techniques, and improve outcomes.

4. Additive manufacturing

Additive manufacturing (AM) delivers a host of advantages that align with the challenges of patient-specific design, in particular developing devices and techniques for unique anatomy and physiology. Advantages of AM include:

High-mix, low-volume

AM enables the manufacture of a high variety of products at very low volumes, often volumes of one. As the opposite of mass production, AM is ideal for patient-specific design.

Complex design capabilities

Because 3D printing builds up products layer by layer, the manufacturing process is essentially the same regardless of product complexity. 3D printing can reproduce complex structures that are impossible to manufacture using any other means.

Rapid prototyping and manufacture

AM lends itself to rapid prototyping, which allows much faster product development and manufacturing. Because there is no tooling involved, it’s possible print a prototype on demand, analyse it, and improve it quickly.

Diverse processes and materials

A wide range of AM processes are used in healthcare, including tools, instruments, implants, prostheses, and anatomical models. The most common materials are thermoplastics, photopolymers and metals, including titanium alloys.

Requirements-driven design

Additive manufacturing supports requirements-driven design, not limited by traditional manufacturing techniques. In many cases, design tools can help generate designs that meet specific criteria for strength, stiffness, weight and other factors.

The future of patient-specific design

The growing popularity of patient-specific design is encouraging healthcare professionals to explore its potential.

One emerging trend is point-of-care manufacture, in which hospitals are maintaining complete 3D printing capabilities in house. With the right software and hardware, healthcare organisations can move efficiently from patient imaging to modelling to production.

This approach requires approved workflows to ensure high-quality results regardless of which facility produces the device. Nevertheless, on-site printing of highly accurate patient-specific medical devices is a promising indication of the power of patient-specific design.