Manufacturers are under pressure to bring better products to market quicker than ever before. Competition is fierce. Margins are tight.

In response to this challenging business environment, the metrology technology market has to be fast-paced and dynamic. Today, we are capable of things that just a few years ago we thought were impossible. To better solve our customers’ measurement challenges, our research teams are constantly addressing new measurement applications and technologies. This demands speed and agility: if we don’t develop continuously, we basically go backwards.

For many years, a clear metrology trend in most sectors is to put measurement directly in the manufacturing environment, where process improvements can be the most beneficial.

Since portable measuring arms made their debut over 50 years ago, user experience and innovation have led to today’s state-of-the-art arms, ensuring they continue to bring tremendous value by combining easy portability with simple usability to make the measurement of small to medium parts easier.

What else have users been asking for? Where has Hexagon applied its R&D efforts?

Today, manufacturers increasingly expect their metrology equipment to operate in ever more harsh environments without the loss of accuracy and precision. Also, the importance of usability cannot be overstated; we’re constantly looking for ways that make it easier for the user – even for less experienced operators – to just get on with measurement. This is especially beneficial given the increasing skills gap with highly skilled engineers retiring and not enough people to fill the gaps. In the US alone there is predicted to be over 2 million unfilled manufacturing jobs by 2030.

How the latest Absolute Arm responds to changing needs for measurement solutions

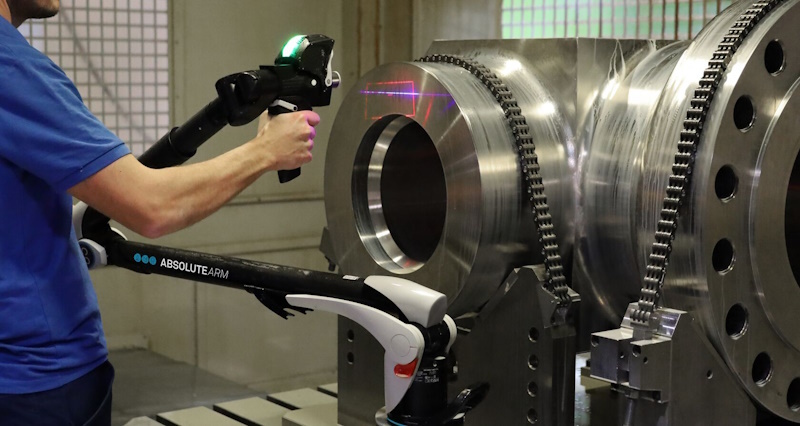

Since Hexagon launched its eighth generation of portable measuring arm – the Absolute Arm, development hasn’t stopped. Unsurprisingly, productivity improvement is the goal. To this end, we’ve focussed on robustness, accuracy and ease of use.

For several years we’ve seen an ongoing migration in where our customers measure their parts. Instead of the metrology rooms of old, we now regularly see the Absolute Arm measuring in harsh non-metrological environments, like next to sheet metal presses or in foundries and aircraft hangars. In those environments you can find all of metrology’s worst nightmares. There’s oil, vibration, dust and often steep changes in temperature. From a product development perspective, we feel a duty to ensure that the Absolute Arm has all the features necessary to measure accurately and quickly in those difficult contexts.

To offer the best protection available against water and particle ingress, we brought IP54 protection to the Absolute Arm in 2022:We want our users to be able to concentrate on their engineering problem during measurement, and not worry about keeping the arm clean in dusty and wet conditions. They want reassurance that their product can measure anywhere and confidence in the most demanding production environments.

For better, more versatile measurement across a broad range of applications, the Absolute Scanner AS1 laser scanner was launched in 2021, IP54 protection added in 2022 and the AS1’s large volume sibling, the Absolute Scanner AS1-XL introduced in 2023.

What we have done with this new revision continues that logic: we really want the Absolute Arm to measure anywhere, so one of its new features, collaborative feedback, consists of new sensors in the arm that notify the user if anything happens in the arm’s working environment that could compromise the quality of the measurement.

Sensors alert the user about vibrations or displacement and provide collaborative feedback

If the arm is measuring in a warehouse and there are trucks or forklifts moving around, it’s possible that they cause vibrations which affect the measurement. Our sensors will alert the user about those vibrations. They can then decide how to mitigate without losing any of the measurement data already taken.

“A funnier example might be when a colleague comes and leans on (or worse, kicks) the arm’s stand – believe me, it happens!”

It can seem quite harmless, but the arm could easily have moved by more than half a millimetre. That might make all previous measurements redundant. By telling the operator when this happens (it could even happen while they’re out at lunch), again, they can take actions to ensure there’s no loss of accuracy, and the part is measured correctly first time. You have greater confidence in your measurements.

Portable measuring arms: Accurate, robust, and easy to use for everyone

Has accuracy improved in this new arm? Yes.

By making some changes to the design of the arm’s core frame, we’ve improved its torsional rigidity, which improves repeatability and reproducibility. We’re very pleased that these improvements are all internal and cannot be seen.

But to be frank, these days we don’t see accuracy as the main difference between a good measurement system and a bad one, just as you don’t judge a car on only its top speed. Of course, better accuracy is always a good thing, but our main priority – and this aligns tightly with what our customers are asking for – is user experience. User feedback told us that a more ergonomic, more usable arm was increasingly important to users. So our engineers focused as much on increased usability as they have on maintaining high-end accuracy.

There’s no point in having great accuracy if it can only be achieved by the experts. Instead, we want the Absolute Arm to be easy, comfortable and intuitive to use, so that our quoted accuracy is always accessible to all users, regardless of the operator’s experience. They should be able switch on the arm and start measuring, with no complications.

The latest Absolute Arm prioritises ease of use and reliability in challenging environments. With features like collaborative feedback and an advanced frame structure, precise measurements are attainable by all users. This release is a continuation of our efforts to deliver cutting-edge solutions that meet the rapidly evolving demands of modern manufacturing.

What about the next iteration of the portable measuring arm?

There is an exciting future for the many flavours of portable metrology solutions. Research and development continues at pace so look out for more updates in the near future. Regarding the next iteration of the Absolute Arm, all we can say is watch this space.

Now we want to hear from you. What are your biggest metrology challenges? Do you use a portable measuring arm in your organisation, and if so, for what? Let us know and share this blog post with your networks.