Sustainability is about to experience a gear change. The manufacturing sector is on the cusp of a fundamental shift that will catapult our sector from making incremental changes to big leaps driven by intelligent and sustainable manufacturing technology.

To date, our path to green production has been characterised by quick fixes for cost and efficiency that are front-of-mind at a business level or visible at a shop-floor level. We commonly see companies making machines adjustments or switching energy suppliers. This is the low-hanging fruit.

However inflation and legislation are adding fuel to the shift. A spike in the price of energy, the scarcity of raw materials and new compliance measures such as the EU’s Corporate Sustainability Reporting Directive, mean companies are looking to implement longer-term, technology-driven measures that will have a more transformational impact.

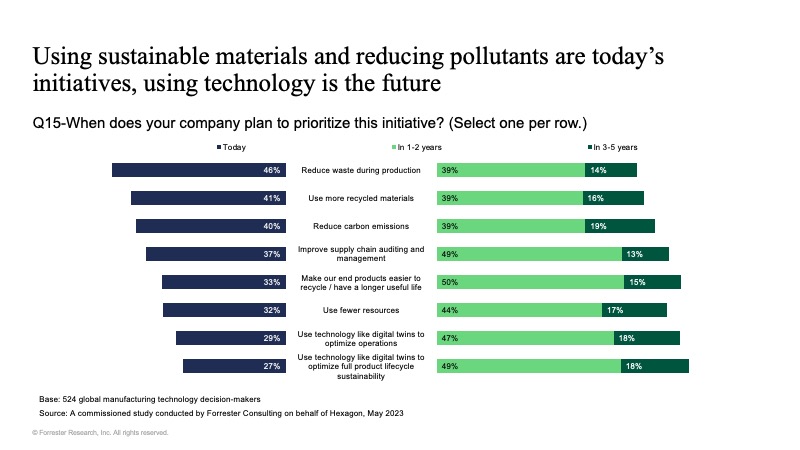

Over the next 1-2 years, industry insiders are telling us they will begin to prioritise activities that accelerate their sustainability efforts while helping meet their own cost and efficiency goals.

Demand for sustainable manufacturing technology

Hexagon’s Advanced Manufacturing Report revealed that 49% of manufacturers plan to improve supply chain auditing and management over the next 1-2 years adding to the 37% already prioritising it. This creates a considerable progress accelerator. Supply-side sustainability efforts drive change from the ground-up globally, setting a high operating benchmark.

Greater supply chain transparency will also give us more data to improve collective decision making across our sector. In 1-2 years when a combined 86% of the industry have improved supply chain auditing and management – it could help us reach a tipping point where there is no room for poor or unsustainable practice.

There is currently a huge logistical task involved with getting data across the supply chain. Addressing this challenge will create innovation, including new tools and platforms for data collection and data sharing.

Quality to become a driver for product sustainability

At the product level, similar efforts are being made to clean up performance. In 1-2 years, 50% of manufacturers plan to prioritise extending the useful life of products and making them easier to recycle. When combined with the 33% already looking at this today – 88% of our industry will be making these important customer quality measures a priority. In the same vein, 44% intend to use fewer resources in 1-2 years’ time with 32% already looking at this.

Reusing materials reduces the pressure on raw materials while longer lasting products reduce the consumer demand for newly manufactured items and raw materials – all good for the planet. The fact that 88% of operators will have made vital adjustments in this area after 1-2 years could set a higher operating standard for product quality. The only choice for those outside this 88% group will be to follow suit to remain competitive.

From tweaks in approach to the potential of technology

With many operational tweaks already underway, manufacturers are seemingly now poised to harness the potential of technology to drive new standards of sustainability.

29% plan to use technology like digital twins to optimise operations today, with a further 47% looking at this in the next 1-2 years. Similarly, 27% are today planning to leverage technology like digital twins to optimise full product lifecycle sustainability, with a further 49% planning to prioritise it in 1-2 years.

Optimisation though is just one side of this. Tools such as digital twin scale optimisation realising major progress leaps from thousands of smaller adjustments. By quickly exploring design possibilities and testing real-world performance in the digital realm – countless optimisations can be made to improve performance and manufacturability.

The other side to digital twin is innovation. It is the fastest way to test and perfect new ideas. Digital twin can show us how things will perform. And when built, real-world data can be used to accelerate optimisation.

Using digital twins to improve products and operations is indicative of a strategy shift. Even with a glance at the above chart shows a visual shift as manufacturers move from more practical to more technology enabled tweaks. This indicates that collectively as a sector we are beginning to think more strategically about the products we make and how we make them.

Generative tools to lift innovation

Adding to simulation is AI, which is already proving its potential to manufacturers, particularly in the area of generative design. By looking at challenges like no human before, algorithms promise to accelerate sustainability progress.

Famously generative design can help with lightweighting, strength, materials testing and overall performance. Despite its relative infancy, it is already making a huge impact in automotive, largely at the performance end of the market. It is teaching us how to combine multiple parts into one housing, for example combining braking and suspension systems. Beyond this, it is opening up entirely new avenues for human designers.

It is fantastic news then that 52% of our industry acknowledge that using automated design optimisation, AI or generative design to augment human innovation, would most benefit their manufacturing processes. Building on this 47% of the sample plan to invest in generative automation over the next three years.

Generative design is just the tip of the iceberg. AI really comes into play when it can mine data and make generative recommendations. This type of innovation touches everything from products to methods of production. Bringing together disparate sets of data, right down to the temperature and humidity in the facility – it can identify problems and make improvements no human could ever spot or consider.

Do we have the data to make sustainable manufacturing technology?

The adoption of tools like digital twin and generative AI will undoubtedly accelerate progress towards sustainability targets. However a big question remains – do we have the data?

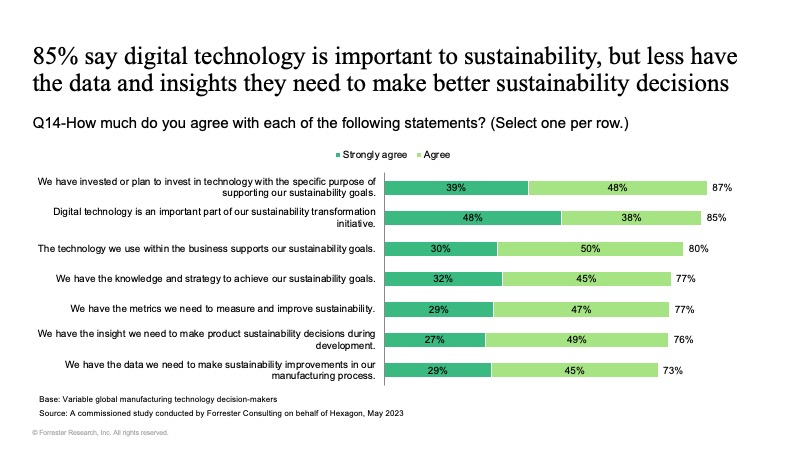

Only around a third of our industry strongly believes the data is in place to make the necessary improvements. Just 29% of our sample strongly agree they have the metrics needed to improve sustainability. The same percentage strongly agreed that they have the data to make sustainability improvements in their manufacturing process. Just 27% strongly agree they have the insight needed to make product sustainability decisions during development.

While larger numbers agree overall with these statements as shown above, it points at a lack of conviction within the sector. If you have the data in place, it tends to be the case that you know it with certainty. Unless you can feel its impact, data is likely to be holding you back.

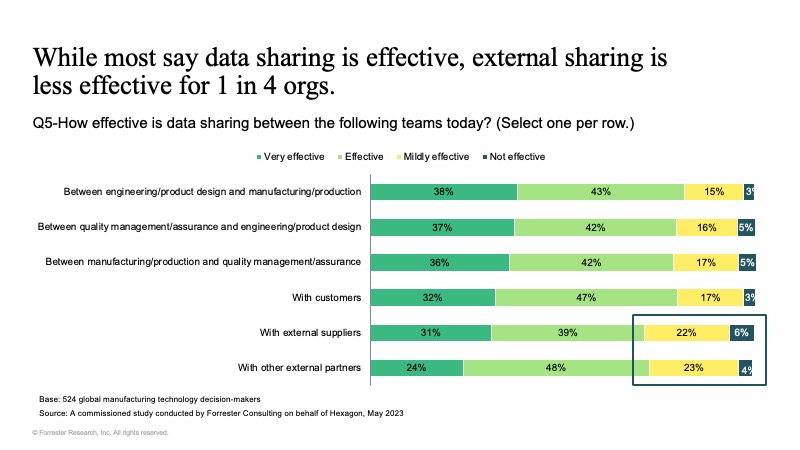

Just as important as factory data is openness and sharing across the supply chain. This is the area of their data flow that manufacturers are least satisfied with.

Improving supply chain transparency by overcoming inter-organisational obstacles is perhaps the biggest single data challenge of the coming years. But once our sector has clear visibility of the supply chain, it will help to deepen customer integration. And it will fuel innovation improving everything from quality to sustainability.

Answering the fundamental question of our time

To set a more positive course for people and planet, we need to scale optimisation and lift innovation and reinvent our ineffective linear business models.

It’s fantastic that our sector is on the cusp of unleashing technology to accelerate progress. All this with specifically with sustainability and efficiency in mind. Tools like digital twin and generative design allow us to entirely rethink the things we make and how we make them.

Beyond the realm of the factory, understanding how we’re connecting data across the entire product lifecycle through the supply chain will help our sector navigate essential change. Ultimately, we need a new circular system for resource capture and remanufacturing. Only then will we meet everybody’s needs in today’s era of resource scarcity and cost inflation.

Over the coming years, technology will power the creation of products that we can currently only dream of. Products that will be made from innovative materials, designed to last and made flexibly and efficiently. These products will exist in a circular economy.

But, to power these leaps we need data. The extent to which data is already in place will vary hugely depending on digital maturity and data management. What we do know is that complete, connected, organised and visible data is central to manufacturing transformation.

Data that is leveraged by technologies like blockchain, digital product passports, digital twin, generative design and modern production methods like 3D printing – becomes the innovation foundation for a new long-term, circular business model that works for everyone.

For manufacturers that place their bets on data, innovation, and the desire to do better – a great future lies ahead.

To understand more about upcoming shifts in manufacturing that will help to shape and refine your strategy, be sure to explore Hexagon’s Advanced Manufacturing Report.