We’ve all seen the distinctive shapes, but what are the major benefits of generative design for manufacturers?

Generative design is a technology with the potential to empower makers in every sector of the global economy. It’s a design process which enhances the potential of humans and machines alike, supercharging innovation. Working from a set of design parameters, generative design programmes use algorithms to create and optimise designs based on the specific goals and constraints of each project and each manufacturing ecosystem.

This is a powerful new technology with a host of benefits. Here are the top 10 benefits of generative design for manufacturers.

1. Lightweighting

In the quest for lightweight products and components, generative design is an exciting tool. By reducing the overall weight of an object, you can improve efficiency, reduce energy consumption and lower operating costs. In sectors like aerospace and automotive manufacturing, this can be a game changing technology. Lighter vehicles have lower environmental impacts, they are easier to transport and they can have improved performance through optimisation.

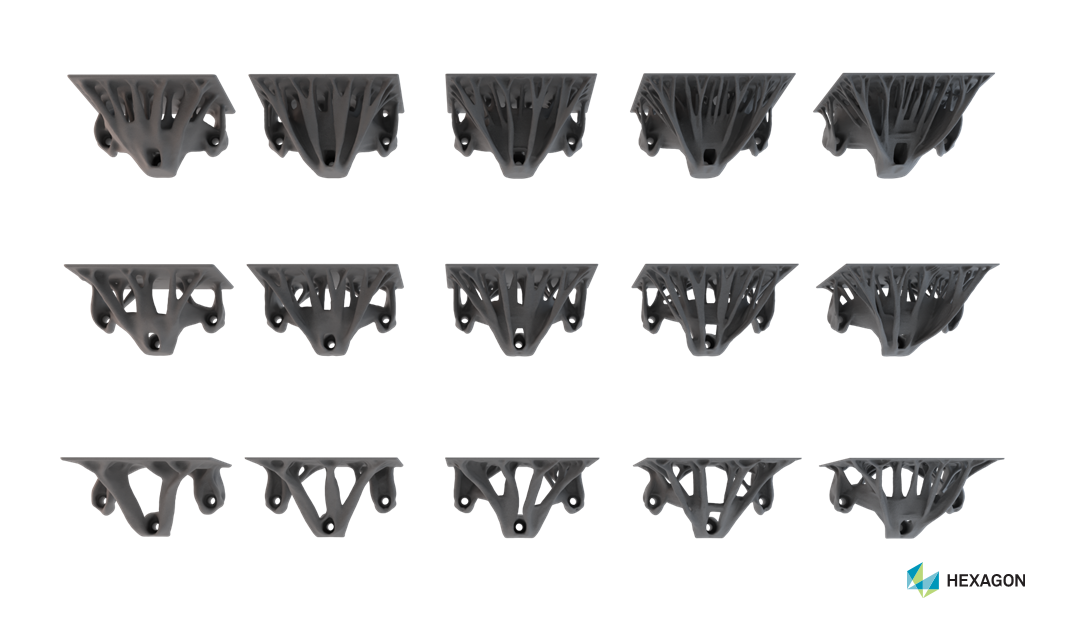

By exploring a vast number of design iterations, we can reduce the weight of a part while still meeting all the requirements of the design specification.

2. Material savings

Lightweight designs are mentioned above, but material savings are worth discussing separately. Generative design algorithms can create a vast number of solutions to a design problem, exploring different shapes, forms and configurations. The software can identify designs that meet specifications while minimising the quantity of material required to achieve the perfect end result.

When you look at designs created generatively, they often have an organic look and feel about them. They require less material while maintaining or increasing strength and durability. When these designs are made with additive methods, the material savings can be very significant.

3. Automation

Businesses that leverage automation can gain a competitive advantage through accelerated innovation and time to market. Generative design automates and optimises the design process in a way that frees engineers from routine work and repetitive, manual processes. Automation improves business resource utilisation, empowering us to redeploy resources in more efficient and effective ways.

Generative design automates design exploration, creating and evaluating many design variants based on the requirements of each project. Now businesses can reduce the time it takes to arrive at an optimal solution. This accelerated design process helps shorten product development cycles, allowing businesses to bring products to market more quickly and gain a competitive edge.

4. Agility and flexibility

Technology moves quickly. In the competitive business environment, the firms that can design, prototype and bring a product to market fastest have a strong advantage. They can respond to customer needs quicker. The ability to pivot from one design to another in response to evolving customer needs is one of the biggest benefits of generative design. It demonstrates a commitment to supporting your clients over the long term, building relationships and establishing yourself as a trusted supplier.

Generative design helps companies become more agile by automating tasks that would take a human designer weeks to complete. By quickly generating and evaluating multiple design options, businesses can save a great deal of time compared to manual methods. Generative design enables rapid iterations and exploration of design possibilities, allowing businesses to identify new and improved solutions faster than ever before.

5. Efficiency

Generative design makes businesses more efficient in several ways. It streamlines the design process which saves time and allows us to explore a wide range of design concepts and make improvements much quicker than with traditional methods.

Another way this technology can improve efficiency is by enabling multiple processes to take place simultaneously. While traditional design takes a sequential approach, generative design can create and evaluate several solutions in parallel. Concurrent design exploration accelerates the process by an order of magnitude, and it frees up staff to explore new avenues for innovation and work on transformation projects.

6. Cost reduction

The greater efficiency of generative design translates directly to cost savings. One of the biggest ways is through material optimisation. Generative design algorithms consider material properties and manufacturing constraints optimising designs for better material usage and less waste.

We also see far greater manufacturing efficiency because bionic shaped designs are much better to produce reducing the machine runtime – the major cost driver for 3D printing.. Every design iteration can be tested and validated in a virtual environment, saving on physical prototypes and rework. This shortens the development cycle and speeds up time to market.

7. Increase innovation

Generative design algorithms create completely new and different solutions which do not depend on legacy designs.

One of the greatest advantages of generative design is that it’s not subject to the inherent biases and preferences of human product designers. When you look at an object created with generative design, they have a seemingly organic structure. It could be considered a form of biomimicry. The software begins with a set of parameters or specifications and generates a series of options that fulfil those requirements. It’s not influenced by legacy designs, or past experiences in the same way a human being would be. This enables the technology to approach each problem with a fresh perspective which results in new ideas and fresh solutions to problems.

8. Access new technology

Generative design is revolutionising access to new technology like additive manufacturing. With its inherent capability to create designs tailored for industrial 3D printing, generative design enables designers to take full advantage of the unique capabilities offered by this advanced manufacturing technique.

Generative design enables companies to embrace and utilise new manufacturing technologies more effectively, fostering innovation and driving industry advancements. When new technologies become available, designers simply adjust the input parameters and the software will create solutions based on that new information.

9. Design for additive manufacturing (DfAM)

Generative design is ideally suited to creating designs for additive manufacturing. The algorithms excel at developing products that maximise the potential of different manufacturing techniques.

With industrial additive manufacturing we can print complex geometries and internal structures that would be very difficult or even impossible to create using other technologies. Generative design is the perfect tool to maximise these capabilities and design features.

10. Reduce reliance on expert knowledge

In a world where technology moves so fast, it’s difficult for staff to keep up to date with the latest skills. By the time a student graduates from college or university, the technology might have progressed to an extent where they need retraining straight away. With some modern technologies, like additive manufacturing, generative design provides a way to combat this problem. By automating processes like design, optimisation and validation, generative design reduces the need for expert knowledge making additive manufacturing a viable option for many more product designers than before.

We hope this article on the 10 benefits of generative design helps you to seize the opportunity to accelerate innovation. Contact us to find out how generative design could improve your business or visit our product pages to read more about this fascinating topic and see how our products can help.